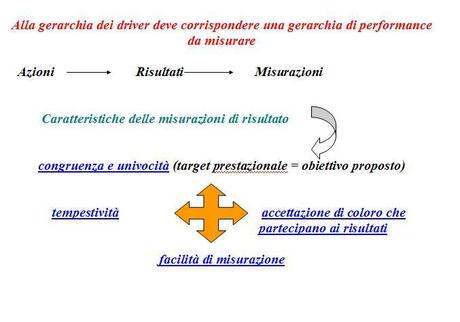

Relying on how properly are organized the activity levels, their correlation with processes guarantee its survival finally. Performance of actions (Miller, 2001) characterize the cornerstone and the widespread denominator of initiatives systematization. For occasion, management would possibly determine that some processes are unnecessary and need to be eradicated or mixed with different processes. Administration may additionally discover that gradual and inefficient manufacturing actions can lead to customer complaints about gradual shipping occasions. Activity-based management (ABM) is a comprehensive approach to bettering an organization’s operational efficiency and strategic decision-making. A risk with ABM is that some activities have an implicit value, not necessarily reflected in a financial worth added to any product.

Corporations that apply ABM can enhance their decision-making course of, which helps in long-term planning. In Addition To, ABM creates a superior understanding of the company’s operation, which leads to environment friendly planning of activities that are prone to increase performance and help worthwhile outcomes. Are you on the lookout for ways to increase your group’s efficiency and productivity? Activity-Based Management (ABM) is an efficient strategy to managing prices and optimizing performance. In this blog, you may study the definition of ABM, uncover its advantages, and explore examples of ABM in motion.

The Function Of Technology In Exercise Primarily Based Administration

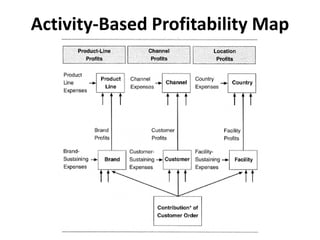

By understanding prices and profitability at the exercise level, it becomes easier to establish areas for enchancment and optimization. Once in place, sustaining price swimming pools and micromanaging assets could eat into your bottom line. Activity-Based Management (ABM) enables organizations to determine and manage actions that add worth and cut back those that don’t.

First, it lowered the number of meter readings to as soon as per yr, and issued invoices primarily based on estimated consumption for the opposite quarters of the yr. It introduced an net site where prospects might enter their own meter readings in the occasion that they weren’t home on the date of the reading, thus decreasing the period of time used by the customer service division. These actions are examples of operational activity-based costing as they relate to lowering the price of existing activities. In ABM however, it’s recognised that the value of a specific exercise might depend on something apart from volume of output.

What Is Abm?

The company had run out of storage space of their main factory in South Avenue, because of a great amount of sluggish shifting stock for their biggest customer, IBM. So extra storage space was rented in Elmore Avenue, a number of kilometres away from South Road. After production, the manuals for all other prospects have been transported to Elmore Avenue for storage. They would then be returned to South Avenue for despatch to the client when required. One Other example might be a company that has opened an workplace in a second location. ABM can help administration assess the costs of the working that location, together with the employees, amenities, and overhead, after which decide whether any subsequent profits are enough to make up for or justify those prices.

- The application of activity-based management (ABM) in the healthcare industry aims to improve operational efficiency and patient outcomes.

- Enhanced effectiveness and efficiencies are expected for both revenue era and price incurrences.

- A case described by Kaplan and Cooper associated to a producer of technical manuals for the computer business.

- Outdoors of the skilled realm, he’s a digital nomad with a ardour for traveling, having lived in many countries across 4 continents.

- Continuous improvement of the group is then achieved utilizing performance measures primarily based on high quality and timelines points for strategically essential actions in the organization.

Order processing high quality would be checked by invoice disputes and credit score note issuance. The info in Table 2 shows that the main value activities of the CC department are pre-sale preparation (handling enquiries and quotes) and post-sale complaints dealing with. Collectively, these activities devour 65% of the sources of the shopper care department. For small companies, or companies with narrow product ranges, the benefits of implementing ABM might not justify the prices. This just isn’t the case, and some overhead prices shall be fastened, so is not going to be saved if actions are lowered.

Integrating Improvement Approaches

However, the complaints dealing with aspect is one, which might be identified as non-value; including in an activity-based administration evaluation. Non-value including actions are these that do not enhance the price of the product to the customer; frequent examples are inspection time and idle time in manufacturing. It is often not possible to eliminate these activities but it is typically attainable to minimise them. Complaints dealing with just isn’t value including as it outcomes from failure to meet the service standards anticipated (and so is already included in the value paid).

ABM implementation can result in improved effectivity and higher profitability for manufacturers. By figuring out specific bottlenecks or inefficiencies in a manufacturing process, manufacturers could make targeted adjustments that lead to increased output and lowered expense. Activity-based costing establishes relationships between overhead costs and actions in order that prices can be extra precisely allocated to merchandise, services, or buyer segments. The advantages of ABM (and ABC) are biggest in organisations which have excessive oblique costs.

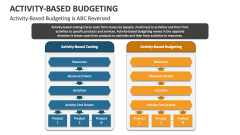

This instance highlights how ABM can address specific operational challenges whereas aligning with broader strategic goals https://www.simple-accounting.org/. By adopting ABM, organizations can move from conventional cost management approaches to a extra dynamic, activity-driven framework, leading to important operational advantages. This approach assigns prices to activities based mostly on their consumption of sources, offering a more correct image of the value of producing products or providing companies. ABM includes breaking down the group’s activities into smaller, extra manageable parts and then analyzing them to determine areas the place enhancements could be made. This might involve eliminating pointless actions, redesigning processes, or reallocating resources to more useful actions.

Conventional value project techniques typically would assign on to the cost objects the costs of these resource consumptions that may be economically traced directly to units of output requiring the assets. The remaining prices, referred to as oblique prices, can be accrued into a number of value pools, which would subsequently be allocated to the cost objects according to volume-related bases of allocation. When different products consume resources at rates that are not accurately reflected of their relative numbers (volumes), a traditional cost allocation strategy will result in product cost cross-subsidization. Activity-based costing tries to take the nonuniformity of resource consumption across products under consideration in the assignment of costs.

For instance, if a material manufacturer runs stitching machines all day for a lot of the 12 months, that shall be thought-about a significant activity. The cost calculation of this exercise will embrace the value of labor, electrical energy, and space required to run the machines. Cloudwards.internet might earn a small fee from some purchases made by way of our web site.